PRODUCTION METHODS

FABRICS

HOW OUR WEAVING MACHINES WORK

Making fabric requires different types of weaving machines, each designed for specific purposes and patterns. These machines work by crossing threads in different ways, from simple hand-operated looms to advanced computerized systems that can create complex designs.

TYPES OF WEAVING MACHINES

There are four types of looms on the market.

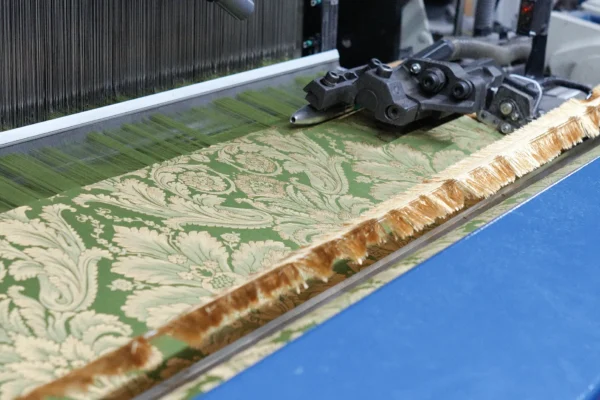

The looms that we use in Sarelli Interiors Textiles are mainly complex jacquard-type looms, with machine dimensions of 165 cm. The looms are used to produce various types of upholstery fabrics of interest to us, such as:

- Jacquard for curtains and upholstery with complex designs.

- Plain fabrics for sheets or linings.

- Damask and brocade for fine decorative elements.

Modern machinery incorporates advanced technologies (such as digital control) to ensure precision, efficiency and the ability to customize textile designs.

JACQUARD LOOM

A Jacquard loom is an advanced type of textile loom that enables the creation of textiles with complex and detailed patterns. This loom is distinguished by the innovation introduced by Joseph Marie Jacquard in 1804, which allows independent control of each warp thread.

FEATURES

PRODUCTION CAPABILITIES

ADVANTAGES

Warp Threads Control

Each thread can be raised or lowered individually, thanks to a perforated card system (in historical versions) or electronic controls in modern looms.

Complex fabrics

Ideal for intricate patterns such as damasks, brocades, elaborate upholstery and decorative fabrics.

Pattern size

Not limited to repetition of small patterns as in traditional looms; allows creation of large designs.

Multicolor

Can use multiple warp and weft threads of different colors to achieve multicolored patterns.

Creative flexibility

Allows the production of fabrics with detailed patterns without requiring changes in mechanical configurations.

Advanced automation

Modern Jacquard looms use computerized systems to quickly program designs.

Precision

Each warp thread can be controlled with extreme precision, ensuring quality and consistency in the result.

FEATURES

Warp Threads Control

Each thread can be raised or lowered individually, thanks to a perforated card system (in historical versions) or electronic controls in modern looms.

PRODUCTION CAPABILITIES

Complex fabrics

Ideal for intricate patterns such as damasks, brocades, elaborate upholstery and decorative fabrics.

Pattern size

Not limited to repetition of small patterns as in traditional looms; allows creation of large designs.

Multicolor

Can use multiple warp and weft threads of different colors to achieve multicolored patterns.

ADVANTAGES

Creative flexibility

Allows the production of fabrics with detailed patterns without requiring changes in mechanical configurations.

Advanced automation

Modern Jacquard looms use computerized systems to quickly program designs.

Precision

Each warp thread can be controlled with extreme precision, ensuring quality and consistency in the result.

WEAVING MACHINE OPERATION

Looms for the production of upholstery fabrics work by following basic weaving principles, combining warp and weft threads to create fabrics with specific characteristics.

COMPONENTS

WARP: Set of parallel threads stretched across the loom,

which form the structure of the fabric.

WEFT: Threads that are woven through the warp, forming the pattern and structure of the fabric.

COMB: Tool that compacts the weft threads in the fabric, ensuring uniform density.

HEALDS: Devices that raise and lower the warp threads to create the space where the weft will pass through (called a passage).

SHUTTLE OR RAPIER: A system that inserts the weft threads into the warp, either manually or automatically.

WEAVING PROCESS

WARP PREPARATION: The threads are arranged parallel on a subbio (winding cylinder) and stretched on the loom.

WARP SEPARATION: Healds raise and lower the warp threads, creating an opening (passage) through which the weft passes.

WEFT INSERTION: The weft is inserted through the warp using a shuttle or other automated mechanism.

BEATING: The comb pushes the weft thread against the already formed fabric, compacting it.

REPEAT: The cycle continues until the desired fabric is obtained.